- Home

- About Us

- Products

Iron & Steel

Building Materials

Fire & Safety Products

Electricals & Electronics

Plastic & PVC Products

- Titanium

- Quality

- Infrastructure

- Contact Us

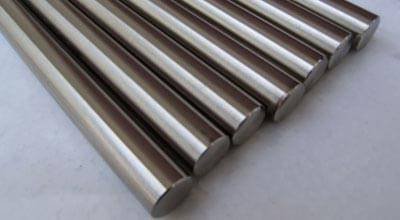

Titanium Grades 1, 2, 3, and 4 commercially 99 percent pure Titanium. Titanium Grade 2 Round Bars are the most often used of the four commercially pure titanium grades for most industrial applications requiring ductility and corrosion resistance. The chemical makeup of each grade varies somewhat, affecting mechanical qualities and design capabilities. Titanium Grade 2 Round Bars are lightweight, corrosion resistant, and frequently outperforms stainless steel corrosion resistance in most conditions.

This Titanium Grade 2 is comprises of several chemicals in varying proportions, such as Iron (Fe) 0.30 max, Oxygen (O) 0.25 max, Carbon (C) 0.08 max, Nitrogen (N) 0.03 max, and Hydrogen2,3 (H) 0.015 max. Titanium Grade 2 is ductile, allowing for cold formability. The material is also simple to maChina, hot work, and weld. Hot work should be done at temperatures ranging from 400 ° F to 600 ° F. Heating at a temperature between 900 ° F and 1100 ° F, followed by either forced air or gentle cooling, should be used to relieve stress. We also have different grades of Titanium Round Bars like Titanium Grade 23 Round Bars, Titanium Grade 5 Round Bars, etc.

The corrosion resistance is due to the formation of a firmly adherent, stable, protective oxide film in the presence of oxygen. This film protects commercially pure Ti Gr from most oxidizing, neutral, and inhibited reducing conditions, as well as slightly reducing situations.

Titanium Grade 2 Round Bars and Titanium Grade 5 Round Bars are resistant to saltwater and marine atmospheric corrosion. Corrosion resistance is similar throughout the four classes; however mechanical qualities differ due to differences in oxygen and iron concentration. Titanium grade 2 Round Bars are resistant to attack by wet chlorides and metallic chlorides, chlorite and hypochlorite solutions, nitric and chromic acids, organic acids, and a variety of gaseous industrial uses.

Grade 2 Titanium Round Bars are commonly used in oil and gas components, reaction and pressure vessels, tubing or pipe systems, heat exchangers, liners, flue-gas desulphurization systems, and a variety of other industrial components. Temperatures in constant service can reach up to 800 Degree F, with intermittent service exceeding 1000 Degree F.

Is good Titanium Grade 2 Round Bars?

Titanium Grade 2 Round Bars can be a good choice for certain applications due to their high strength-to-weight ratio, corrosion resistance, biocompatibility, & ability to withstand high temperatures. It depends on the specific requirements of an application

What is the Grade 2 titanium round bar used for?

Titanium Round Bar is used for applications where weight reduction, strength, corrosion resistance, & biocompatibility are important, such as in aerospace, medical & chemical processing industries.

importance of Titanium Grade 2 Round Bars?

Round Bars are important because they offer a unique combination of properties, including a high strength-to-weight ratio, corrosion resistance, biocompatibility, & the ability to withstand high temperatures also these properties make them a valuable choice for applications where weight reduction, strength, and resistance to harsh conditions are important considerations, such as in the aerospace, medical, and chemical processing industries.

Shubham Metals Is India’s Leading Supplier Of High-quality Metal And Stainless Steel Products. We Offer A Wide Range Of Durable, Reliable, And Cost-effective Solutions For All Your Industrial And Commercial Needs. Trust Shubham Metal For Excellence And Quality.